Appendices

ENVIRONMENTAL PERFORMANCE

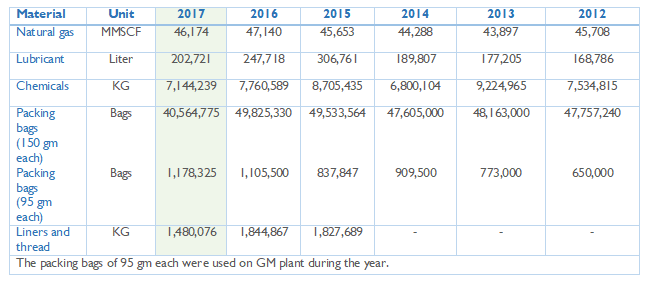

MATERIAL CONSUMPTION

FFC does not use renewable material in the production processes.

RECYCLED MATERIAL CONSUMPTION

FFC tries, wherever possible, to use recycled materials but due to the nature of the production process, recycled raw materials cannot be used. Moreover, the cleanliness requirements do not allow the use of such materials. However, during the year urea dust of 9, 866 MT was recovered and used in the process. Our products are dissolved during use and are not reclaimable. Moreover, the packaging material is biodegradable. We have not reclaimed product or packaging materials.

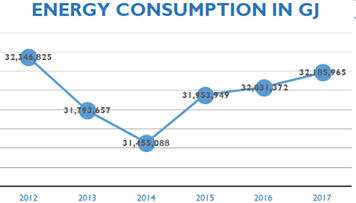

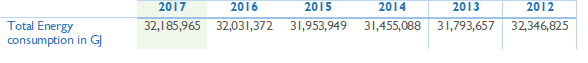

ENERGY CONSUMPTION WITHIN ORGANIZATION

FFC’s plants primarily need energy in the form of steam, electricity and natural gas. FFC uses natural gas for heating, and generating electricity and steam in its own power plants. Main primary energy source is natural gas. FFC endeavors, however, to explore the possibilities of renewable energy generation and increase the share of energy obtained from renewable sources on an ongoing basis.

FFC uses self-generated electricity for heating and cooling purposes. No electricity, heating or cooling is purchased or sold from/to external parties. The conversion factors were source from Energy Information Administration USA.

ENERGY CONSUMPTION OUTSIDE ORGANIZATION

FFC does not purchase electricity or steam from external sources. There is no indirect energy use resulting from purchase of electricity, heat or steam. However, other indirect energy use from operations are measured and recorded, where possible.

We have identified that the indirect energy used by us is not significant in the overall context. For example, energy consumption caused by travelling of FFC employees is insignificant in relation to overall consumption.

Moreover, with more than 3,300 staff, the cost of determining the indirect energy consumption by employees traveling to the company would not be appropriate given the level of insight this would provide. As such, an investigation of this kind will not be conducted. However, the company has made an effort in determination of energy consumption relating to the fuel used in company vehicles at plant sites, head office, and plant site employees travelling by air during the year. The energy consumption as a result of these activities is 36,926 GJ.

ENERGY REDUCTIONS

FFC product is dissolved in soil during usage and not energy intensive. However, the company has been striving to reduce the energy consumption requirement during production process through implementation of programs and projects aimed at reducing energy consumption for a number of years. These measures are bearing fruit and FFC’s production is becoming significantly more energy-efficient over the years. However, the energy consumption has increased by 0.26 GJ/MT in the year 2017 as compared to 0.14 GJ/MT reduction in previous year due to upcoming plant turnaround.

FFC runs three plants located at two manufacturing sites. The plants having different technologies, which have different energy intensity ratios. The overall energy intensity ratio was 12.81 GJ/MT urea as compared to the last year intensity ratio of 12.69 GJ/MT. The energy intensity ratio includes only scope I energy consumption figures.

Energy consumption data is recorded in relevant conventional unit, for instance MMSCF in the case of natural gas and kWh for electricity. These units are converted into the consolidation unit, gigajoules (GJ), to obtain the mean energy content. This is then used as a standard measure for representing energy consumption. The energy consumption and energy sources in this report have been determined from the data provided by the production sites. They, therefore, provide a consolidated and comprehensive picture of FFC’s energy usage in manufacturing operations. The heating values were calculated on the basis of laboratory analysis and standard heating values for natural gas and diesel.

WATER USE

FFC mainly needs water for production of steam and cooling purposes. The water requirements are met for the most part by canal water. Before the water flows into the piping system of plant site, the canal water is cleaned according to its intended purpose using various filter systems. FFC’s both plants draw canal water up to maximum 18 cusec during the year. The canal is managed by the Irrigation Department and this withdrawal is not significant keeping in view the annual flow of the canal. FFC has an agreement with the Irrigation Department and the meters installed by the department measure the water inflow. There are no protected species found in the canal and the canal water is mainly used for irrigation purposes. The tube wells are used occasionally when the canal water is not available. The company has a large area where tube wells are installed and the water withdrawal from tube wells does not significantly impair the water system.

FFC uses the-state-of-the-art machinery to continuously circulate and capture the water after use in order to re-cool it for reusing. This environmentally friendly cooling method is used where technically possible. Water recycling reduced during the year due to leakage in exchanger which resulted in steam venting causing low recovery. The problem was identified during detailed inspection of the exchanger and has been fixed during the year.

WASTEWATER

FFC uses water for a variety of purposes in the production process. The water is partly polluted as a result therefore the production wastewater is treated to reduce the pollutants to acceptable limits, prescribed by NEQS, before using and discharging into canal water. FFC uses oil skimming and neutralization method for waste water treatment. In the season, when canal is closed, the water is stored in evaporation ponds. In contrast, cooling water along with rain water can be fed into canal without cleaning as it does not come into contact with chemicals. The wastewater is also used for horticulture purposes at plant sites.

FFC’s plant sites are certified against environmental standard ISO-14001:2004. All the emissions are within the prescribed NEQS limits and regularly reported to the EPA under SMART reporting program. The wastewater discharged by FFC is largely cleaned and therefore does not burden the environment excessively.

Please download pdf report from the menu on left for futher details.